About Me

My name is Taylor Stansfield and I am a senior mechanical engineering student at the University of Michigan. This past summer, I worked as a mechanical engineering intern at Logic Robotics, responsible for a project which I saw from concept through manufacturing. This experience was focused on mechanical design using engineering fundamentals, as well as evaluating different manufacturing methods and DFM. Other than my internship experience, I was part of Michigan’s Rocketry club and the BIRDs lab multi-legged robotics research team. As a member of the rocketry club, I worked with fellow students to build and test assemblies for our ground support equipment. On my research team, I worked on testing and data collection for gait optimization for robot locomotion. In University of Michigan course work, my projects have included developing electromechanical systems, control design, and engineering testing and documentation.

Projects

ICE Cold Enclosure - Logic Robotics

May 2025 - August 2025

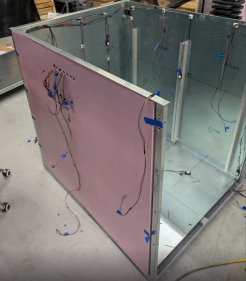

ICE is a 40x48x48 inch cooler prototype for cold-chain logistics that can interface with Logic’s robotic pallets. The requirements for my design were that it could hold 1800lbs, stay below freezing for 17 hours, and only impede inwards on the 40x48 inch pallet space by one inch. The result of my work was a highly optimized cooler that contained a welded structural frame to hold ICE’s sheet metal walls, and utilized PCM plates to maintain a consistent temperature while having walls only 1 inch in width, achieving all requirements set for it. ICE will be used for transportation and storage of refrigerated goods.

Utilized skills

I created a Python simulation for modeling heat transfer into the cooler to predict thermal losses, helping to understand the optimal insulation thickness.

I performed structural calculations for beam stress and deflection to inform the creation of custom-designed internal frame, ensuring ICE could hold 1800lbs when supported from its corners when resting on a pallet rack.

In meetings with manufacturers, I presented engineering drawings I created to build ICE’s custom frame and sheet metal walls.

Once the design was finalized, I manufactured several metal and polymer components in-house using a mill, lathe, and power tools.

Exploded view of completed CAD assembly

Partially completed assembly showing insulation and thermocouples

FEA of welded internal frame

Python simulation of heat transfer with varying insulation thickness

MuRoAM Research team - BIRDs Lab

January 2025 - September 2025

As part of the MuRoAM research team, I collected data and made design choices focused on gait optimization for multilegged robots. One goal of my work was to maximize the efficiency of locomotion for the BIRDs’ lab fastANT robot by employing steel legs to convert the robots friction-based motion to momentum-based. I also worked on the Octobot subteam, collecting motion capture data to understand the capabilities of the modular robot’s locomotion. By using the motion capture data, we could better understand the tradeoffs between speed and agility. The data I collected was also used to program Octobot to be controlled by a joystick instead of manual inputs.

Utilized skills

I used motion capture software to collect position and movement data to analyze for gait optimization.

As part of improving fastANT’s agility, I worked as part of a team performing dynamic testing to outline its toe path throughout its strides.

I performed regular maintenance and troubleshooting on both FastANT and Octobot robots.

As part of material selection for fastANT’s spring legs, I conducted literature reviews on the flexibility of various steel alloys.

Octobot walking with MoCap tracking markers

FastANT suspended for motor calibration

Dynamic testing of FastANT’s spring steel toe path

OctoBot’s MoCap data displayed in 3D

ME395 - Engineering Laboratory

January 2025 - May 2025

MECHENG 395 was a laboratory class where we were given case studies and collected data to provide recommendations to engineering companies. I worked both on teams and individually to generate reports in which data was analyzed and conclusions were drawn to inform stakeholders of possible improvements to their designs. From thermal system optimization to airfoil testing, this course covered a variety of engineering testing methods.

Utilized skills

I performed complex data analysis in MATLAB, presenting my findings clearly in various graphs and tables.

I used error analysis methods to determine the uncertainty of all data I collected, ensuring I could be confident in my results and recommendations.

From the data obtained through testing, I generated models in MATLAB to predict system behavior and extrapolate to real-world cases.

Figures and Tables from report on cam and follower dynamics

ME350 - Design and Mfg II

August 2024 - December 2024

In one of our core engineering classes, we were tasked with developing a linkage and control system to shine a flashlight onto various targets as part of a competition. I was personally responsible for designing the linkage, which was optimized for weight, efficiency, and stability. This work included tolerance measurements, joint stackups, MBD analysis, and developing PID controls. Our linkage received 28 out of 31 points in competition, along with scoring high marks for its lightweight and ergonomic design.

Utilized skills

I used Solidworks to create the linkage assembly, specifically using DFM principles knowing what was available to us in the university machine shop.

Once the designs were completed, I used the mill, lathe, and waterjet to manufacture components.

Using the results of Adams MBD simulations, I designed the transmission system to deliver the optimal torque and speed to the linkage

I programmed an Arduino to control a stepper motor with PID controls, ensuring the resolution through the transmission was precise enough to hit all targets.

Final assembly fastened to playing field

CAD of linkage and transmission assembly

Adams simulation of linkage movement

Michigan Aeronautic Students Association (MASA) - ATLO subteam

September 2023 - August 2024

As a member of the Michigan Aeronautic Students Association’s (MASA) assembly, test, and launch operations subteam, I contributed to the design and manufacturing of our ground support equipment system. I designed the LOx and fuel tank mounting structure, which held five pressurized tanks containing cryogenic fluid, weighing up to 250lbs each. This fixed the tanks in place, ensuring they would not have to be removed or adjusted during the GSE’s semester long use and 2200 mile trip to the Mojave desert. I also conducted tests with a team on GSE components such as our custom-built flowmeter, collecting critical data while ensuring the test followed SOP and safety standards. I also worked on a team which performed coldflows of the GSE system once it was complete to prepare for the eventual hotfire test of the rocket engine.

Utilized skills

I used NX software to create CAD parts and assemblies for FEA simulation and laser cutting.

To ensure my design met its requirements, I performed structural load and safety calculations.

I manufactured tubing for plumbing on the GSE system by hand.

In order to perform tests, I read and reviewed SOPs to ensure I was aware the testing and safety procedures.

When assembling the GSE system, I prepared components to meet LOx cleanliness standards

Completed GSE system with plumbing and tanks

CAD of initial mounting assembly

Tanks installed on completed mounts